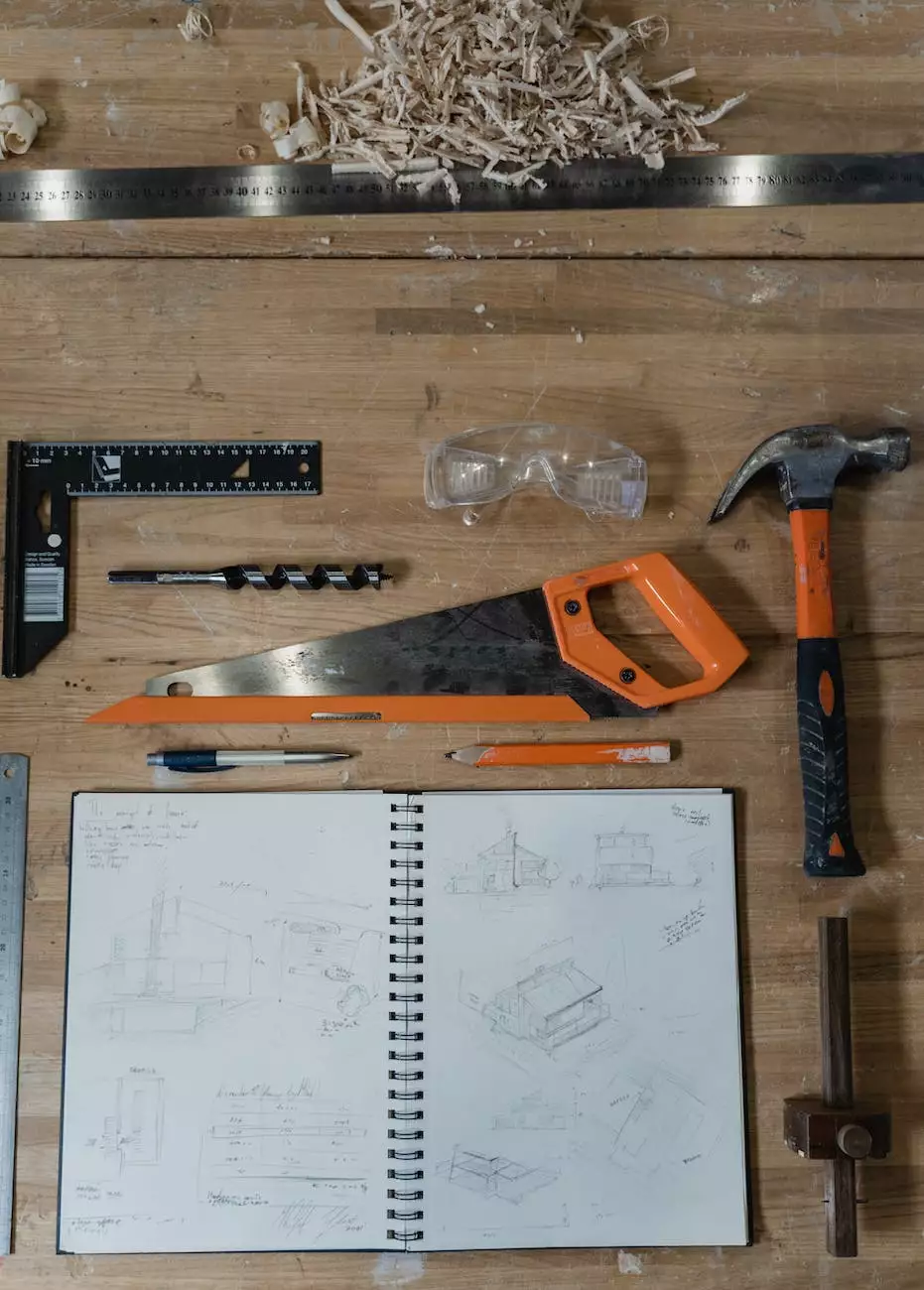

Types Of Bits Used By An Air Hammer

Welcome to SEO Company Kansas City's comprehensive guide on the various types of bits used by an air hammer. In this article, we will delve into different air hammer bits, their features, and applications in order to provide you with a comprehensive understanding of this versatile tool.

The Importance of Choosing the Right Bits

When it comes to using an air hammer, selecting the right bit is crucial. The correct bit can significantly enhance efficiency and productivity, while a wrong one can lead to subpar results, downtime, and even damage to both the tool and the workpiece. With numerous options available, it's essential to understand the different types of bits to ensure you're equipped with the right tools for your specific needs.

Chisel Bits

One of the most commonly used types of bits for air hammers is the chisel bit. These bits feature a sharp cutting edge and are available in various shapes and sizes, including flat, pointed, and round. Chisel bits are perfect for tasks such as chipping away concrete, removing rust, or cutting through metal. They provide excellent control and precision, making them versatile and suitable for multiple applications.

Punch Bits

If you're looking to create holes in metals or other hard materials, punch bits are the ideal choice. These bits have a pointed tip and are specifically designed for punching holes with ease and accuracy. Punch bits come in different sizes to accommodate various hole diameters, making them a must-have for any air hammer toolkit.

Cutting or Scrapper Bits

When your project involves cutting through or scraping materials, such as removing paint, old adhesive, or welding slag, cutting or scrapper bits are the go-to option. These bits are equipped with flat, wide blades that allow for smooth and efficient material removal. Whether you're working on a construction site or involved in metal fabrication, cutting or scrapper bits are indispensable tools for precise and swift material removal.

Rivet Buster Bits

Rivet buster bits are primarily used for heavy-duty demolition or industrial applications. These bits have a chisel-like design, but instead of a pointed tip, they feature a wider and more robust blade. Rivet buster bits are perfect for breaking up concrete, removing rivets, or chipping away hardened materials. Their durability and strength make them the preferred choice for professionals in demanding industries.

Carbide Bits

For tougher materials such as masonry or hardened steel, carbide bits are a game-changer. These specialty bits are constructed with carbide tips that ensure extended durability and superior resistance to wear. Carbide bits offer exceptional performance in applications like removing tile adhesive, breaking up concrete, or cutting through rebar. If you frequently work with hard materials, carbide bits are a worthwhile investment.

Conclusion

When it comes to air hammer bits, choosing the right type for your specific task is vital. This comprehensive guide from SEO Company Kansas City has explored the various types of bits used by air hammers, including chisel bits, punch bits, cutting or scrapper bits, rivet buster bits, and carbide bits. Each variety offers distinct features and applications to ensure optimal performance and efficiency.

We hope this guide has provided you with valuable insights into the different air hammer bit options available. By understanding the characteristics and applications of each type, you can make informed decisions and select the most suitable bits for your projects. Remember, the right bit can make all the difference in achieving outstanding results with your air hammer.