Everything You Need to Learn About Stainless Steel Fabrication

Introduction

SEO Company Kansas City is here to provide you with comprehensive information about stainless steel fabrication. Our expert Business and Consumer Services - SEO services can help your website rank higher on Google by optimizing your content and utilizing effective SEO strategies. Below, we will explore the world of stainless steel fabrication, covering its processes, benefits, applications, and more.

What is Stainless Steel Fabrication?

Stainless steel fabrication refers to the process of shaping, cutting, and assembling stainless steel materials to create various products. It involves a combination of techniques such as welding, forming, machining, and finishing. This versatile material is widely used in industries such as construction, automotive, aerospace, and more, thanks to its exceptional properties and durability.

Benefits of Stainless Steel Fabrication

Stainless steel fabrication offers numerous benefits, making it a popular choice for various applications:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it suitable for environments with high humidity, chemicals, or salt exposure.

- Strength and Durability: Stainless steel exhibits excellent strength and durability, ensuring longevity and reliability for fabricated products.

- Aesthetic Appeal: Stainless steel provides a sleek and modern appearance, making it an attractive choice for architectural and design purposes.

- Heat and Fire Resistance: Stainless steel can withstand high temperatures and fire, making it ideal for applications that involve heat or flames.

- Hygiene and Cleanliness: Stainless steel's smooth surface is easy to clean, making it suitable for industries requiring high sanitation standards, such as healthcare and food processing.

The Stainless Steel Fabrication Process

The stainless steel fabrication process involves several stages:

- Design: The fabrication process begins with detailed design plans. The design considers the project requirements, dimensions, and specifications.

- Material Selection: Choosing the appropriate stainless steel grade is crucial for achieving the desired mechanical and corrosion-resistant properties.

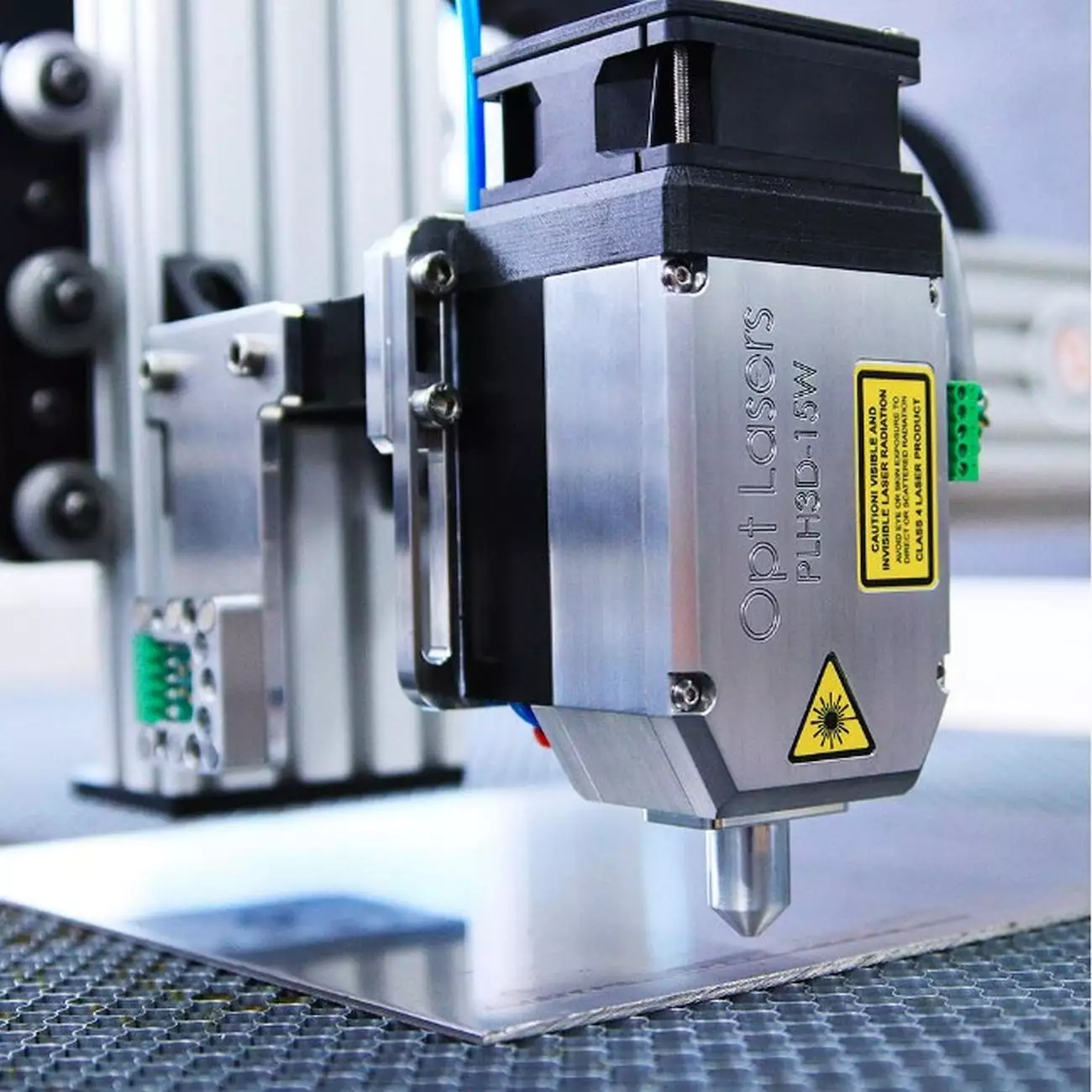

- Cutting and Shaping: Stainless steel materials are cut and shaped according to the design using various techniques such as sawing, shearing, laser cutting, or plasma cutting.

- Forming: Forming processes such as bending, rolling, or stamping are employed to shape the stainless steel into the desired forms, such as plates, sheets, or tubes.

- Welding: Welding techniques, including TIG or MIG welding, are used to join the stainless steel components together.

- Finishing: Surface finishing techniques like polishing, grinding, or coating are applied to enhance the appearance and improve the surface properties of the fabricated stainless steel products.

- Quality Assurance and Inspection: Rigorous quality checks ensure that the fabricated stainless steel products meet the required standards and specifications.

Applications of Stainless Steel Fabrication

Stainless steel fabrication finds extensive use in a wide range of industries and applications:

- Architecture and Construction: Stainless steel is utilized in building facades, handrails, structural components, and roofing systems due to its strength, durability, and aesthetic appeal.

- Automotive: Stainless steel is used in various automotive parts, such as exhaust systems, fuel tanks, brackets, and decorative trims, for its resistance to heat and corrosion.

- Aerospace and Aviation: Stainless steel's ability to withstand extreme temperatures and harsh conditions makes it an ideal choice for aircraft components, engine parts, and structural elements.

- Food and Beverage Industry: Stainless steel fabrication is commonly employed in manufacturing equipment, storage tanks, and food processing machinery due to its hygienic properties and corrosion resistance.

- Medical and Healthcare: Stainless steel is used in the production of surgical instruments, medical equipment, hospital furniture, and implants due to its biocompatibility, sterilization capabilities, and corrosion resistance.

- Oil and Gas: Stainless steel's excellent resistance to corrosion and harsh environments makes it suitable for offshore platforms, pipelines, storage tanks, and refineries.

Conclusion

In summary, stainless steel fabrication is a versatile process that enables the creation of durable, corrosion-resistant, and aesthetically pleasing products. From the design stage to the final finishing touches, every step in the fabrication process requires expertise and precision.

SEO Company Kansas City, with our expertise in the field of Business and Consumer Services - SEO services, can help you optimize your website and outrank competitors in search engine results. Contact us today to learn more about how we can assist you in achieving higher rankings and driving more organic traffic to your site.